2025-04-12

Do you know the application of ultrasonic Electrolytic hydrogen spraying coating?

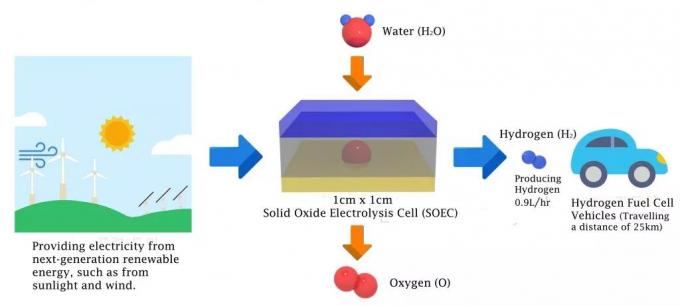

Ultrasonic atomization spraying electrolytic hydrogen production is a technology that applies ultrasonic atomization spraying technology to the field of electrolytic hydrogen production to improve the efficiency and performance of electrolytic hydrogen production. Electrolytic hydrogen production generates hydrogen and oxygen by electrolyzing water. In the electrolytic cell, a pair of electrodes immersed in the electrolyte are separated by a diaphragm to prevent gas penetration. When a certain voltage of direct current is passed, water decomposes.

Principle: Ultrasonic atomization spraying technology uses the energy of ultrasonic waves to convert high-frequency sound waves into mechanical energy through piezoelectric transducers, and then applies mechanical energy to liquids to generate standing waves in the liquid film at the top of the ultrasonic nozzle. These stationary liquid waves extend upward from the top of the ultrasonic nozzle. When the droplets leave the atomization surface of the nozzle, they are decomposed into a uniform fine mist of micron-level or even nano-level droplets, and then evenly coated on the surface of the substrate by a certain amount of carrier gas to form a coating or film.

Advantages: It has the advantages of high coating uniformity, high raw material utilization, high coating thickness control accuracy, thinner coating thickness, less splashing, no nozzle clogging, and low maintenance cost.

Application of ultrasonic spraying in electrolytic hydrogen production

Electrode coating formation: The catalytic material required for electrolytic hydrogen production is evenly sprayed on the electrode surface. Through ultrasonic spraying, the coating particles can be better dispersed and more closely combined with the electrode surface, improving the adhesion and stability of the coating, effectively increasing the surface area and activity of the electrode, and thus improving the efficiency and hydrogen production rate of electrolytic hydrogen production.

Electrode cleaning: During the electrolytic hydrogen production process, the electrode surface may be contaminated by oxides, impurities or sediments, reducing the electrolysis efficiency. The ultrasonic vibration generated by the ultrasonic spraying system can effectively remove pollutants on the electrode surface, improve the cleanliness of the electrode, and ensure the stability and continuity of the electrolytic hydrogen production process.

![]()

The significance of ultrasonic atomization spraying for electrolytic hydrogen production

It can improve the protection effect and service life of the electrode, reduce the direct contact between the electrode and the electrolyte, and thus reduce the degree of corrosion and oxidation. At the same time, due to its characteristics such as precise control and high material utilization, it can reduce production costs and environmental impact, meet the needs of different electrolytic hydrogen production processes, ensure the quality and stability of the coating, and help promote the development and application of electrolytic hydrogen production technology.

Among several major water electrolysis technologies, proton exchange membrane water electrolysis (PEM) is considered to be an ideal choice for coupling with renewable energy. Ultrasonic atomization spraying technology has broad application prospects in PEM electrolytic hydrogen production. For example, when preparing the electrode coating of the PEM electrolyzer, it can accurately control the catalyst loading and coating thickness, improve the performance and stability of the electrode, and thus improve the overall efficiency and economy of the PEM electrolytic hydrogen production system.

Ultrasonic atomization spraying can improve the efficiency of electrolytic hydrogen production by optimizing electrode performance, promoting electrolyte diffusion and bubble discharge, as follows:

Optimize electrode performance

Improve catalyst loading uniformity: Ultrasonic atomization spraying can atomize the catalyst solution into tiny droplets and spray them evenly on the electrode surface. This allows the catalyst to be more evenly distributed on the electrode, the active sites to be fully utilized, and the actual reaction area of the electrode to be effectively increased, so that the electrolysis reaction can proceed more fully, thereby improving the efficiency of hydrogen production.

Enhance the bonding force between the coating and the electrode: During the spraying process, this technology uses the energy of ultrasound to better embed the catalyst particles into the electrode surface to form a strong bond. This not only improves the stability of the coating and reduces the shedding of the catalyst during the electrolysis process, but also reduces the contact resistance between the electrode and the coating, making the electron transmission smoother and accelerating the electrolysis reaction rate.

Accurately control the coating thickness: Ultrasonic atomization spraying can accurately control the thickness of the catalyst coating. The appropriate coating thickness can ensure that the catalyst has enough active sites to participate in the reaction, and can also avoid the ion diffusion path being too long due to the excessive thickness of the coating, thereby improving the efficiency of the electrolysis reaction.

Promote electrolyte diffusion

Improve electrolyte distribution: In the electrolytic cell, ultrasonic atomization spraying can evenly distribute the electrolyte on the electrode surface and nearby areas. This helps maintain the uniformity of the electrolyte composition on the electrode surface, avoids the reduction of reaction rate caused by local concentration differences, makes the electrolysis reaction more uniform over the entire electrode surface, and improves the overall hydrogen production efficiency.

Accelerate ion transmission: The vibration of ultrasound can promote the transmission of ions in the electrolyte. On the one hand, vibration accelerates the diffusion rate of ions in the electrolyte. On the other hand, it also helps to break the diffusion layer on the electrode surface, making it easier for ions to reach the electrode surface to participate in the reaction, thereby increasing the rate of electrolysis reaction and thus improving the efficiency of hydrogen production.

![]()

Facilitates bubble discharge

Reduce bubble size: The ultrasonic cavitation effect generated during ultrasonic atomization spraying can break the bubbles in the electrolyte into smaller bubbles. Small bubbles have less adhesion to the electrode surface and are more likely to detach from the electrode surface, thereby reducing the adhesion of bubbles to the electrode surface and increasing the effective reaction area of the electrode.

Promote bubble detachment: The vibration of ultrasound can destroy the adhesion stability of bubbles on the electrode surface, making it easier for bubbles to detach from the electrode surface under the action of buoyancy and liquid flow. Timely discharge of bubbles can prevent bubbles from gathering on the electrode surface, hindering the contact between the electrolyte and the electrode, thereby improving the efficiency of hydrogen production by electrolysis.

Send your inquiry directly to us